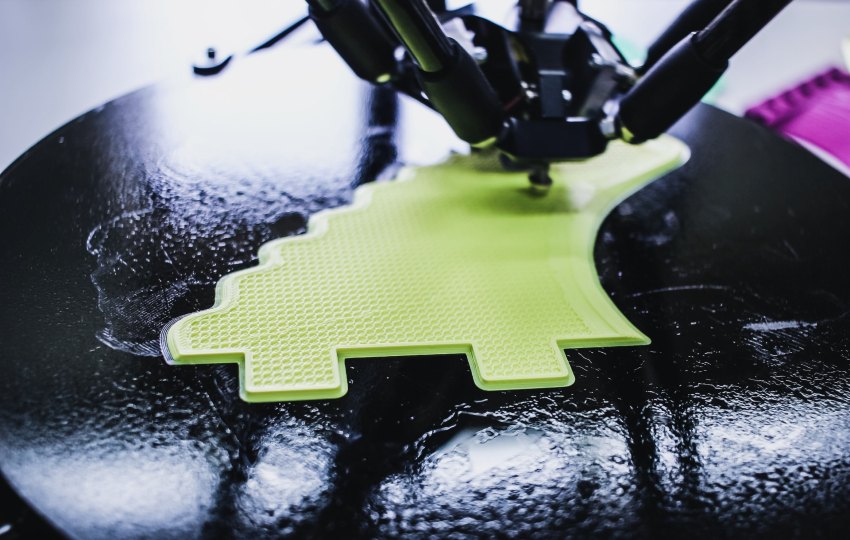

The benefits of 3D printing have never been in doubt. It has drastically changed the way a lot of companies do business. It’s definitely a worthwhile investment and the global 3D printing market size is expected to reach a value of $76 billion by 2030. But the profitability it brings is not the sole reason why this technology has become so popular these days. It is heralded as a better alternative to traditional manufacturing because it is a more environmentally-friendly and sustainable manufacturing method.

But is it really? Sustainability has three cardinal rules – reduce, reuse, and recycle. If 3D printing is to be considered a sustainable manufacturing method, then it should be able to follow these three rules.

Reduce

The objective of the three R’s of sustainability is to prevent waste and conserve natural resources. The first R, Reduce, means to use fewer resources to manufacture, transport, and dispose of products. These actions, in turn, help minimize the number of new resources that will be used.

3D Printing Reduces Waste

Traditional manufacturing methods involve cutting away from a massive block of material to form a product, much like what a sculptor does to create art. Obviously, there’s a lot of waste produced by this method. In fact, the material waste often reaches more than 50% of the starting material.

Additive manufacturing, or 3D printing, involves building an object layer by layer after creating a model using a 3D modeling software. It doesn’t use up more material than it requires. Therefore, it doesn’t produce as much waste as traditional manufacturing methods – around 70% to 90% less waste compared to CNC manufacturing or injection molding. Another reason why this technology produces less waste is that most of the design process is done using simulation software which means fewer prototypes are made and less waste generated. CNC machining can also be utilized to produce highly precise 3D printed parts.

However, that does not mean that 3D printing does not produce any waste at all. There are certain cases where it does:

- First, there are designs which require the printing of support structures which will prevent the part from getting deformed during the process. Once printing is completed, those support structures will be removed, becoming waste. The amount is minimal but still needs to be considered. The same goes for post-processing.

- Another instance where 3D printing can produce waste is through failed parts. Your first print isn’t going to turn out perfectly right off the bat. Creating a successful 3D print design can be challenging for beginners which can result in failed prints before you get it right. That being said, it can be avoided using advanced simulation software. But if you’re not so sure about your skills, it might be better for the environment (and your pocket) to leave the printing to the experts like an online 3D printing service.

3D Printing Reduces Emissions

It’s not just the amount of waste that is reduced by utilizing 3D printing as a manufacturing method. It’s also the amount of CO2 emissions.

In fact, according to a groundbreaking study conducted in 2014, this disruptive technology will be cutting the amount of emissions by as much as 5% by 2025. There are a number of reasons why 3D printing can do this.

First, 3D printing eliminates the need for transporting and storage of products. Companies won’t need trucks driving across states to transport parts because they can produce them on site.

In addition, 3D printing is a more efficient manufacturing process than most conventional manufacturing methods. It uses less energy to produce products, especially when the design has been optimized.

Reuse

Reuse is defined as the use of materials more than once in their original form, rather than throwing them away after one use. By reusing materials, we prevent new resources from being used while ensuring that old materials do not enter the waste stream.

3D Printing Reuses Materials

3D printing is a manufacturing process that is able to reuse certain materials such as thermoplastics. A lot of plastic filaments produced come from recycled plastic.

That’s not all. Studies have shown that metal powders that remain unmelted after a printing process can be reused in future projects. The remaining metal powder just needs to be sieved and then mixed with new, unused powder to become viable again. Not only does this make 3D printing more sustainable, it also makes the process more economical since metal powders do not come cheap.

Recycle

Recycling is simply when you use waste materials, changing them from their original forms, and making them into new products. While recycling takes energy, it does prevent the use of new resources while keeping old materials from going into the waste stream.

3D Printing Recycles Materials

Did you know that you can convert your 3D printing fails into material for your future projects? A 3D printer filament recycler will break your failed prints into bits and pieces before melting them and forcing them through an opening. The liquid plastic is cooled down before being coiled into a reel. You can also use a filament extruder – a machine that melts crushed 3D print debris to form new filaments.

Another way to recycle 3D printing materials is to use a special extruder that you can attach to your 3D printer. This piece of equipment will allow you to directly use recycled plastic pieces for printing.

The Bottomline

3D printing is by no means a magical cure for the ails of our environment. And it isn’t a perfect process either. It can still produce waste and use a huge amount of energy. However, when compared to traditional manufacturing methods, it is more efficient and saves more resources than it uses up. While it isn’t exactly “green” technology, it comes closer to making a difference in a world moving towards sustainability.

Louisa Allen

Louisa is a content marketing professional and editor creating her successful career past 2 years at D3D Printing. She is a goal-oriented, creative individual with a unique voice in writing, editing, and optimizing content for various projects. She’s a devoted mom and an excellent piano player.